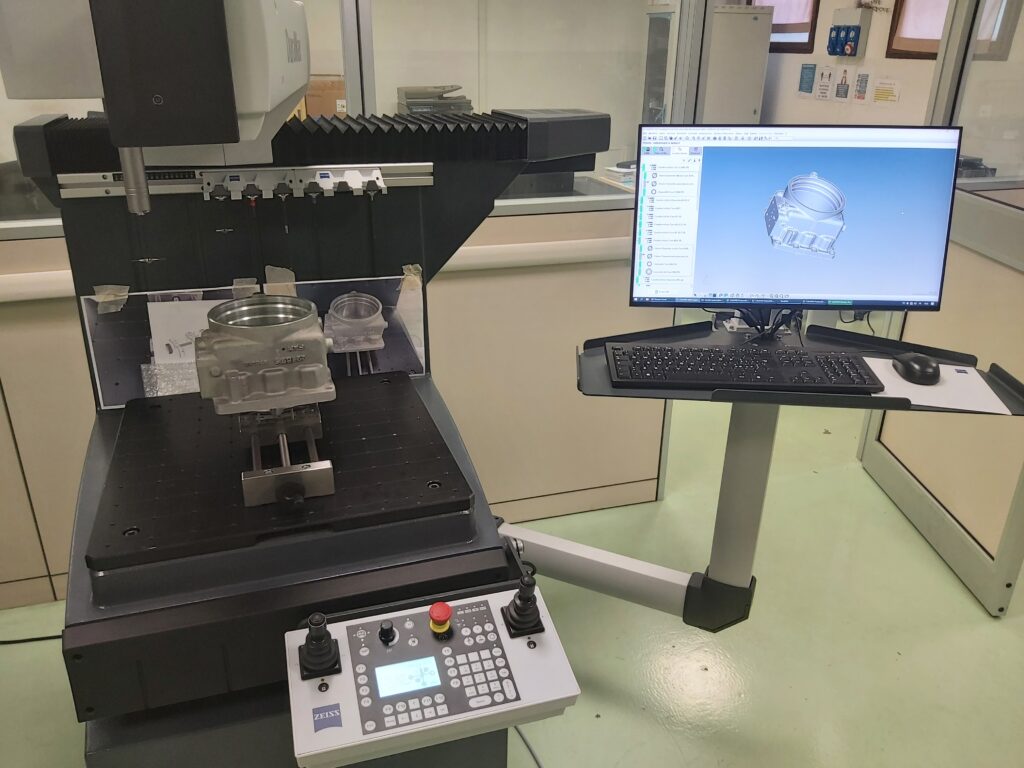

An metrology room of excellence allows CMS to guarantee the quality requested by the customer. After CNC machining and on-board measurements, the pieces are inspected by the quality control department equipped with the best CNC three-dimensional measuring machines as well as measuring instruments traditionaland for the creation (at the customer’s request) ofdetailed reports of the measurements performed.

We have the best measuring machines and equipment currently on the market, installed in a thermostabilized room, which allow us to verify the quality of the mechanical processes strong> carried out both during the production process and before actual delivery to the customer:

- ZEISS ACCURA 2

Continuous scanning metrological control machine

X1200 Y1800 Z1000 (mm) - ZEISS DURAMAX

Macchina per controllo metrologico a scansione continua

X500 Y500 Z500 (mm) - Mitutoyo Formtracer Avant c4500

System for measuring profiles and surface roughness - Mitutoyo sj-410

Roughness meter - TESA Micro-Hite 3D

Manual 3D measuring machine

440 x 500 x 420 mm